Supply Chain Collapse Preparation Guide: Practical Tips for Navigating Supply Chain Disruptions

Supply Chain Disruptions: Internal Or External Factors

Why should we worry about things going wrong with how goods get from those who make them to those who buy them?

Supply chains are like the hidden wires that keep our world running, ensuring everything from food to phones gets to us without a hitch and at good prices.

A strong supply chain enhances livelihoods by giving affordable access to essential items and reducing the processing time from production to consumer.

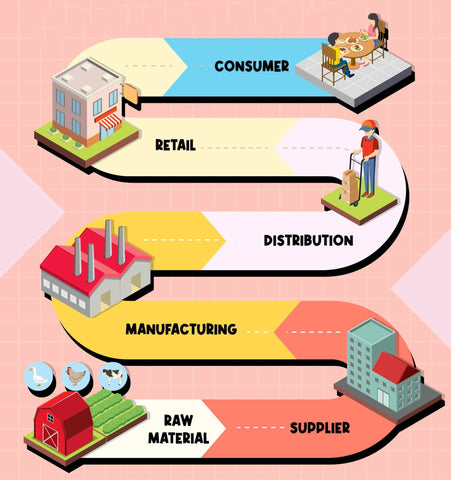

But, as far as disruptions are concerned, they are highly disruptive aspects of our current systems as they affect the production, distribution, and consumption of many products at every level across the globe- from manufacturers to raw material producers and distributors, transporters, retailers, and consumers.

Here’s a supply chain diagram that is easy to follow. It visually represents the flow from suppliers to consumers, including each key component: supply chains involve components such as suppliers, manufacturers, distributors, retailers, and consumers.

This article discusses why these problems happen, how they can affect everyone, from big companies to us at home, and what we can do about it.

We'll break down the tricky stuff into simple ideas and share tips to help businesses and regular individuals deal with these challenges.

By the end, you'll know more about keeping things moving smoothly, even when surprises come our way.

There are two expansive kinds of supply chain disruptions: Internal and External.

Sometimes, the trouble comes from within, like when companies make mistakes, use old tech, or need to be more organized.

Other times, big problems come from outside, like bad weather, strikes, or even big political changes, things you can't control but still have to deal with.

Internal Factors

Inefficiencies within supply chain management (SCM), outdated SCM technologies, and human errors, such as inaccurate data entries, can significantly disrupt operations.

One of the most important contributions of efficient supply chain management for a manufacturer is that it can assist in aligning supply and demand mechanisms by ensuring the products arrive at their destinations on time and in a profitable manner.

For instance, automation in the supply chain can boost efficiency, while accurate data can streamline order processes, saving costs in the long run.

External Factors

These include uncontrollable events such as major weather incidents, strikes, or geopolitical events like wars and trade embargoes.

Although manufacturers have limited control over these external risks, they can mitigate their impact.

Strategies such as diversifying suppliers and shipping routes can reduce vulnerability to these disruptions.

Recent Supply Chain Disruptions: The COVID-19 Pandemic

The COVID-19 pandemic has reshaped the landscape of global supply chains, presenting challenges and disruptions on an unprecedented scale.

As companies and logistics operations grapple with the fallout, the resilience and adaptability of supply chains have never been more critical.

Overview of Supply Chain Disruptions

- Global Impact: The pandemic led to widespread shortages, affecting everything from household essentials to critical tech components.

- Statistics Highlight: A report by Randstad noted a 63.8% increase in global supply chain disruptions in the first half of 2021 alone.

Immediate Responses to Disruptions

- Adaptive Measures: Businesses were forced to rapidly alter their supply chain strategies, seeking new distributors and raw material sources.

- Logistics Sector Efforts: Organizations in the logistics industry worked diligently to mitigate disruptions for their clients.

Long-term Adaptations

- Resilience Building: Surviving companies have been revisiting and reinforcing their supply chains to withstand future shocks.

- Real-life Example: During the pandemic's peak, the scarcity of face masks and sanitizers illustrated the immediate impact of supply chain breakdowns on everyday life.

The Ongoing Challenge

- Factory and Production Recovery: Despite a return to operation since mid-2020, continuous virus outbreaks pose ongoing challenges.

- Vaccination and Variants: While vaccines have allowed some regions to ease restrictions, misinformation, vaccine inaccessibility, and new variants have prolonged supply chain pressures.

Specific Adaptations by Companies

- Tech Industry Innovations: Companies like Apple and Samsung accelerated the adoption of digital and automation technologies in manufacturing and logistics to cope with demand fluctuations and workforce shortages.

- Pharmaceutical Sector: Pfizer and Moderna restructured their logistics for ultra-cold storage capabilities, ensuring the safe distribution of COVID-19 vaccines despite logistical hurdles.

Data and Statistics on Impact

- Semiconductor Shortages: The automotive industry faced a production loss of over 3 million vehicles in 2021 due to semiconductor shortages, highlighting the cascading effects of supply chain disruptions.

- Increased Logistics Costs: Shipping costs skyrocketed, with container shipping rates from China to the US increasing by over 300% from pre-pandemic levels, according to data from the Freightos Baltic Index.

The COVID-19 pandemic has underscored the fragility and complexity of global supply chains, compelling companies across industries to rethink and fortify their supply chain and logistics strategies.

Through innovation, diversification, and strategic planning, businesses are navigating these turbulent times, laying the groundwork for more resilient and responsive supply chains in the future.

The Concept of Supply Chain Resilience

In today's fast-paced and interconnected world, the resilience of supply chains has become a critical aspect of business strategy, ensuring continuity and reliability in the face of disruptions.

Supply chain resilience is not just about bouncing back from challenges; it's about foreseeing, adapting, and thriving amid various risks and uncertainties.

The Essence of Supply Chain Resilience

At its core, supply chain resilience is about maintaining stability and responsiveness in uncertain times.

- Rapid Response: Quickly adjusting to material sourcing and logistics disruptions.

- Quality and Quantity Assurance: Ensuring the continued provision of services and goods despite challenges.

Characteristics of a Strong Supply Chain

A strong supply chain is distinguished by its toughness and flexibility, allowing it to bounce back from setbacks.

- Resistance: Ability to withstand the impact of shortages and facilitate recovery.

- Proactive Mitigation: Reducing the effects of potential disruptions and limiting their impact.

Risks and Disruptions

Navigating the complexities of supply chain risks is essential for safeguarding against operational pitfalls.

- Functional Risks: Threats that can compromise different parts of the supply chain, affecting overall business agility.

- Interference Impact: The potential to undermine business operations and resilience.

Building a Resilient Supply Chain

Creating a resilient supply chain involves forward-thinking strategies and adopting advanced technologies.

- Innovative Processes: Utilizing modern supply chain technologies for forecasting and anticipating risks.

- Agility and Adaptability: Designed to quickly respond to threats and opportunities, ensuring longevity and success.

Supply chain resilience embodies the strategic foresight and operational flexibility required to navigate the complexities of modern business landscapes.

By emphasizing resistance, recovery, and proactive adaptation, businesses can safeguard their operations against various risks, ensuring sustainable growth and competitive advantage in an ever-changing world.

Three (3) Must-Do Steps And Preparation For Supply Chain Disruptions

Supply chain disruptions can significantly impact businesses and individuals, requiring proactive steps and preparations to mitigate risks.

By adopting a strategic approach to manage these challenges, entities can enhance their resilience against unforeseen disruptions.

1. Stockpiling Essentials And Managing Inventory

To safeguard against supply chain disruptions, it's essential to maintain a robust inventory of critical supplies. This approach ensures continuity in operations, even during unexpected shortages.

At Home:

- Food and Water: Maintain a seven-day supply of non-perishable food items and water, focusing on products that require no refrigeration and are low in salt.

- Emergency Supplies: Keep a stash of essential emergency items such as flashlights, a manual can opener, a radio, batteries, and copies of important documents.

- Storage Tips: Start by calculating your family's daily food consumption, multiply by seven for a week's supply, and gradually increase your stockpile by purchasing a bit extra each week.

In the Office:

- Inventory Tracking: Employ an efficient system for inventory management, ranging from manual record-keeping for small offices to inventory management software for larger operations.

- Stock Management: Use software to monitor stock levels and receive alerts when supplies run low, ensuring a continuous supply of necessary office materials.

- Supply Management Role: Designate an office supply manager to oversee inventory software, ensuring a streamlined process for stock management.

2. Developing A Personal or Business Contingency Plan

A contingency plan is crucial for both personal and business contexts, preparing for potential supply chain disruptions with strategic planning and resource allocation.

- Resource Assessment: Identify internal and external resources available for incident management, including emergency services and contractors.

- Emergency Procedures: Outline critical procedures for disruptions, clearly define roles and responsibilities, and establish protocols for emergency responders.

- Risk Analysis: Evaluate the vulnerabilities within your supply chain to prioritize areas for securing alternative sources and plan for environmental, social, and political factors that could affect supply routes.

3. Building A Nearby Network of Suppliers And Resources

Diversifying your network of suppliers is a proactive measure to ensure the continuous availability of products, even when primary suppliers cannot deliver.

- Supplier Diversification: Identify alternative suppliers in various geographic locations to ensure product availability from different sources.

- Supply Chain Flexibility: By establishing connections with suppliers in different regions, you can enhance the resilience of your supply chain against localized disruptions.

- Expertise in Supply Chain Management: Engage with supply chain and fulfillment experts who can guide disruptions, offer alternative courier solutions, and navigate the challenges of additional costs and surcharges.

These steps prepare businesses and individuals for supply chain disruptions and strengthen operational resilience.

Long-Term Supply Chain Strategies: A Step Closer To A Resilient Supply Chain

Creating a resilient supply chain is crucial for businesses navigating through unpredictable disruptions effectively. The PPRR (Prevention, Preparedness, Response, and Recovery) model is a comprehensive framework for reducing the impact of supply chain disruptions.

Emphasizing the importance of a risk management plan, this approach addresses both external and internal threats to maintain continuity and efficiency.

Here’s how companies can apply long-term strategies to enhance their supply chain resilience:

Enhance Providers Via Supply Diversification

Diversifying suppliers helps mitigate risks associated with reliance on a single source for essential components. This strategy has been successfully implemented across various industries:

- Automotive Industry: Companies like Toyota have adopted a multi-supplier strategy for critical parts to avoid shortages caused by natural disasters or geopolitical tensions.

- Electronics Sector: Tech giants, such as Apple, source components from multiple suppliers across different regions to minimize the impact of supply chain disruptions.

Strategy Implementation

- Strategic Supplier Partnerships: Establish relationships with multiple suppliers in different geographic locations to reduce dependency on a single source.

- Regional Diversification: Identify suppliers from various regions to safeguard against localized disruptions.

Technology And Automation

Adopting technology and automation enhances communication with suppliers and improves supply chain efficiency:

- Cisco Systems: Utilizes advanced supplier relationship management software to streamline supplier communication and collaboration.

- Amazon: Employs warehouse automation and robotics to optimize inventory management and efficiently fulfill orders, even during peak demand.

Strategy Implementation

- Supplier Communication Tools: Implement systems for automatic order delay notifications, enabling proactive adjustments to production schedules.

- Predictive Analytics and AI: Use data analytics and artificial intelligence to predict future disruptions and optimize supply chain decisions.

Focus On Supply Chain Visibility

Gaining visibility into the supply chain allows companies to monitor and manage the flow of goods more effectively:

- Walmart: Uses an advanced logistics system to track products from suppliers to distribution centers and retail outlets, ensuring high supply chain visibility.

- Maersk: The shipping giant uses digital tracking to give customers real-time cargo location and status information.

Strategy Implementation

- Integrated Tracking Systems: Implement technologies that offer real-time tracking of products throughout the supply chain.

- Data Sharing Platforms: Foster collaborative networks that facilitate supply chain data exchange among stakeholders.

Backup Inventory Investment

Maintaining a backup inventory can prevent shortages and ensure continuity:

- Pharmaceutical Companies: Maintain buffer stocks of critical medicines to manage supply chain risks.

- Food Retailers: Large grocery chains keep additional stocks of non-perishable food items to avoid shortages during peak demand or supply chain interruptions.

Strategy Implementation

- Sustainable Resource Management: Prioritize backup stocks of sustainable resources to align with environmental goals.

- Inventory Analysis: Conduct regular assessments to determine the optimal level of buffer stock based on demand patterns and supply chain risks.

By implementing these strategies, companies can step closer to achieving a resilient supply chain that withstands disruptions and maintains operational integrity.

This approach addresses immediate challenges and paves the way for sustainable growth and competitiveness in the global market.

The Financial Burdens of Supply Chain Disruptions

Navigating the financial burdens of supply chain disruptions requires strategic planning and foresight for individuals and businesses.

These disruptions can lead to increased costs, delayed shipments, and the need for more robust financial buffers. Below are ways to mitigate these financial impacts effectively.

Emergency Fund

An emergency fund is essential for weathering unexpected financial storms caused by supply chain disruptions.

- Purpose: Serve as a financial safety net for unforeseen expenses, ensuring you can cover daily living costs without dipping into long-term savings or accruing debt.

- Size of Fund: Aim to save at least three to six months' worth of living expenses, though the exact amount should be tailored to individual circumstances such as lifestyle, monthly costs, income, and dependents.

- Business Reserves: For businesses, maintain a cash reserve (also known as retained earnings or capital reserves) to cover unexpected operational costs when supply chain issues arise, ensuring continuity.

Budgeting or Budget Planning

Effective budget planning is crucial for businesses to navigate supply chain challenges.

- Visibility: Advocate for transparency in costs and operations to enhance risk management and improve customer experience.

- Value Targeting: Identify and prioritize supply chain budget opportunities by analyzing failure rates, defect rates, and inefficiencies.

- Collaboration and Shared Ownership: Work closely with budget owners across logistics, operating costs, and inventory to align financial planning and operational strategies.

- Accountability and Alignment: Implement reduction targets within the supply chain budget, ensuring stakeholder support for optimization efforts through strategic planning, design, and resource allocation.

- Monitoring and Control: Foster continuous improvement by regularly tracking the supply chain budget's performance against set benchmarks.

Understanding And Managing Supply Chain Costs

Effective management of supply chain costs is vital for sustaining business operations and profitability.

- Types of Costs: Key supply chain costs include facilities and assets, procurement and production, inventory management, transportation, and administrative expenses.

- Streamlining Ordering Processes: Utilize a unified software system for placing orders to simplify procurement and reduce errors.

- Investing in Inventory Management Software: Adopt advanced inventory management solutions to optimize stock levels and reduce holding costs.

- Monitoring Ordering Patterns: Analyze order history to identify trends and areas for improvement in the supply chain.

- Setting KPIs: Establish realistic Key Performance Indicators (KPIs) to measure supply chain performance and identify areas for cost savings.

- Automation: Leverage automation technologies to minimize labor-intensive tasks and reduce overall supply chain costs.

By adopting these strategies, individuals and businesses can better prepare for and mitigate the financial impacts of supply chain disruptions.

This proactive approach ensures financial resilience and supports sustained operational efficiency and competitiveness in the face of supply chain challenges.

Conclusion: The Supply Chain And Its Future Disruption

Supply chain disruptions make startling and questionable times for businesses and consumers. They likewise cause people to notice inventory network conditions they know nothing about when everything works like flawless clockwork.

It can diminish creation, decrease client certainty, lessen deals, and affect income. Regardless of whether you are aware of it or not, it can affect our day-to-day living.

Therefore, follow through with the strategies listed above to mitigate future disruptions of the supply base via personal preparedness, long-term investment technological advantages, or financial preparations for the potential risks of global disruption.

📖 Further Readings: